Masterbatch de desespumación resistente a la humedad para bolsas de camisetas, películas agrícolas y bolsas de compras

Resumen del producto:

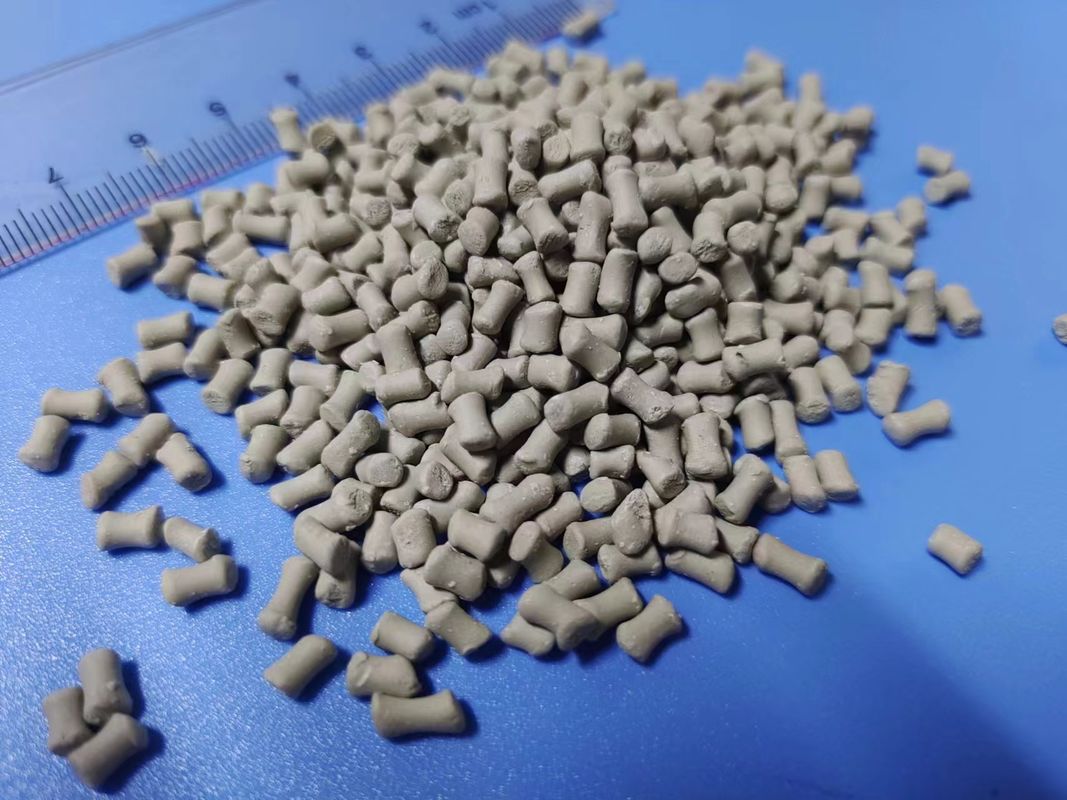

El Masterbatch es un aditivo multifuncional diseñado para contrarrestar la humedad y eliminar la espuma en el procesamiento de plásticos.este masterbatch se incorpora típicamente en una proporción de 2 ∼ 5%.Tiene un índice de flujo de fusión (IFM) de 2 ‰ 20 g/10 min (190 °C, 2,16 kg), un contenido de cenizas ≤ 0,3% y un alargamiento en la ruptura ≥ 200%.Inhibe eficazmente la formación de espuma durante la producción y ofrece una solución integrada para mejorar la eficiencia del proceso y el rendimiento del productoEste masterbatch es particularmente adecuado para aplicaciones que requieren absorción de humedad, propiedades antistaticas y control de espuma.

Características clave:

- El tipo: Masterbatch de desecante y desespumante

- Punto de fusión: 110-130°C

- Contenido volátil: ≤ 0,3%

- Resistencia a la tracciónSe aplican las siguientes medidas:

- Indice de flujo de fusión (190°C, 2,16 kg): 2-20 g/10 min

- Función de desespumación: Rendimiento antiespuma integrado

- Protección contra la humedad: Agente antihumedad eficaz

Parámetros técnicos:

| Propiedad |

Valor |

| Nombre del producto |

Masterbatch de desespumación |

| Uso recomendado |

Entre el 2-5% |

| Apariencia |

Gránulos grises |

| Elongación en la ruptura |

≥ 200% |

| Resistencia al calor |

≥ 80°C |

| Valor del pH |

6 8 |

| Contenido de humedad |

≤ 0,3% |

| Función primaria |

Desicante y antihumedad |

| Densidad |

1.2-1.4 g/cm3 |

| Punto de fusión |

110 a 130°C |

| Resistencia a la tracción |

≥ 3Mpa |

Aplicaciones:

PE-300 Defoaming Masterbatch, fabricado por Ecoplas Material, sirve como un agente antihumedad y antiespuma de alta eficiencia adecuado para una variedad de usos.Se trata de una solución óptima para los sectores que exigen una protección fiable contra la espuma y la humedad, como la producción de bolsas de camisetas., películas agrícolas y bolsas de compras, salvaguardando efectivamente la integridad y el aspecto del producto.que lo convierte en una opción preferida para los fabricantes que buscan mejorar el rendimiento y reducir los defectos.

Apoyo técnico y servicios:

Ofrecemos un amplio soporte técnico y servicios para maximizar la eficacia de nuestro Masterbatch de Desespumación:

El apoyo incluye:

- Asistencia en línea las 24 horas del día

- Formación técnica en profundidad

- Apoyo de ingeniería in situ

- Documentación detallada del producto

- Mejoras frecuentes del producto

Servicios prestados:

- Desarrollo y ensayo de formulaciones personalizadas

- Solución de problemas de proceso y solución de problemas

- Optimización de productos y procesos

- Desarrollo y mejora de aplicaciones específicas

Nuestro equipo dedicado de expertos técnicos está siempre listo para ayudar con las consultas y ayudarle a lograr resultados óptimos con nuestros productos de Masterbatch de Desinfección.

¡Su mensaje debe tener entre 20 y 3.000 caracteres!

¡Su mensaje debe tener entre 20 y 3.000 caracteres! ¡Por favor revise su correo electrónico!

¡Por favor revise su correo electrónico!  ¡Su mensaje debe tener entre 20 y 3.000 caracteres!

¡Su mensaje debe tener entre 20 y 3.000 caracteres! ¡Por favor revise su correo electrónico!

¡Por favor revise su correo electrónico!